Turbine Blades and Vanes

High-Quality hot gas path blades and vanes for inland Gas Turbines

Hot gas path blades and vanes are among the most expensive and difficult to produce spare parts of the turbine.

Quality, along with cost, is the most important parameter to be taken in account during the Purchase.

.

In order to produce high quality aftermarket turbine parts, mastering all the Reverse Engineering processes and the most advanced technologies is a condition but it is not sufficient enough.

Quality with short lead time to market

Special Parts has a long established manufacturing experience for a wide range of Turbine products and long term business relationship with first class manufacturing facilities.

Special Parts's strong coordination with its supply chain Partners during the performance of the Reverse Engineering and Product Development activities guarantees an incredibly efficient and consistent planning of the production process and a highly reduced time to market.

New Production from Samples - Process Phases

Special Parts's Engineers have long experience in develop new products from samples. From Turbine blades to combustion chambers to casings Special Parts handles all the phases of the Reverse Engineering and Development process.

Quality with short lead time to market

Special Parts has a long established manufacturing experience for a wide range of Turbine products and long term business relationship with first class manufacturing facilities.

Special Parts's strong coordination with its supply chain Partners during the performance of the Reverse Engineering and Product Development activities guarantees an incredibly efficient and consistent planning of the production process and a highly reduced time to market.

New Production from Samples - Process Phases

Special Parts's Engineers have long experience in develop new products from samples. From Turbine blades to combustion chambers to casings Special Parts handles all the phases of the Reverse Engineering and Development process.

FIRST PHASE

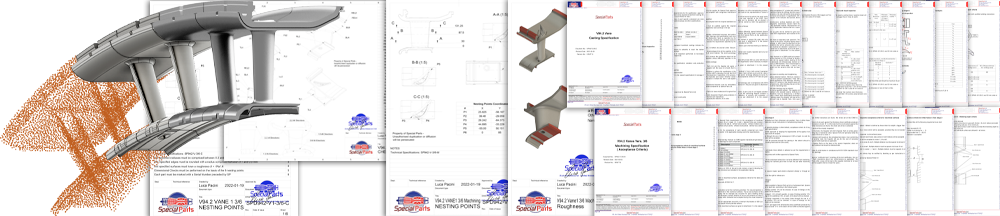

3D SCANNING - DRAWINGS AND MATERIAL SPECIFICATION DRAFTING

One or more samples are used to determine the Material and Shape of the component.

For each stage of the production, complete manufacturing documentation, drawings and Quality Acceptance Protocols are drafted.

SECOND PHASE

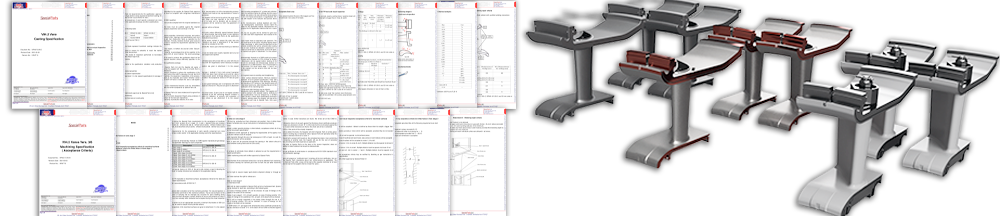

PLANNING OF MANUFACTURING PROCESS AND THE SUPPLY CHAIN SELECTION

The design of all the required tooling is drafted. The planning and the validation of all the production activities is agreed with all the suppliers involved.

THIRD PHASE

TOOLING MANUFACTURING - TRIALS AND FAIR

Under SP Supervision, each company within the supply chain produces several trial parts in order to perfect the manufacturing processes and to guarantee continued repeatability of the quality requirements during the production. All relevant parameters and data are registered in the FAIR (First Article Inspection Report )

FOURTH PHASE

PRESENTATION OF THE FAIR AND CUSTOMER APPROVAL

The complete FAIR is consigned to the customer for its evaluation and approval. The production is ready to start

.

Blades and Vanes for Gas turbine Hot Gas Path are extremely difficult components to produce and cannot be manufactured in one single plant. Typically parts are produced in a lost wax investment casting foundry, refined in a superalloy machining shop and finished in a coating shop.

SP role is to distribute to each plant the necessary drawings and manufacturing specification, to manage the supply chain and to check the quality of each production process.

SP role is to distribute to each plant the necessary drawings and manufacturing specification, to manage the supply chain and to check the quality of each production process.

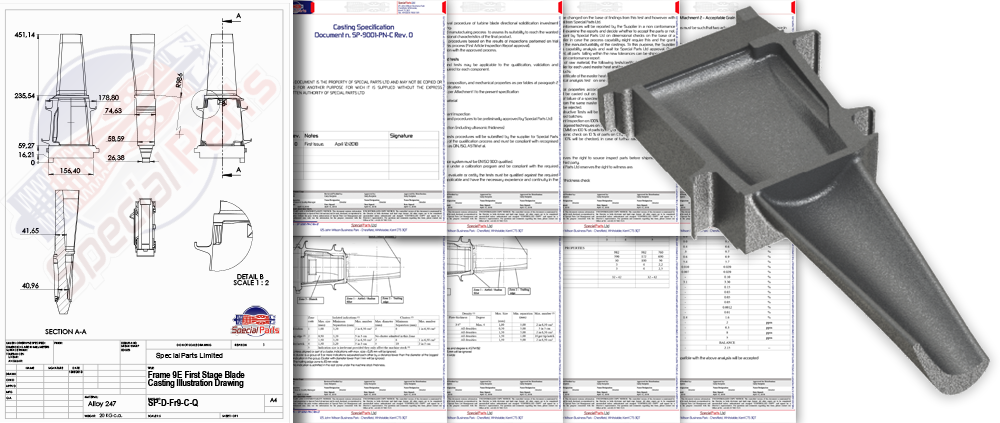

FIRST PHASE

Casting

Components are casted in according with Special Parts drawing and specification in some of the most renowned foundries in Western Europe. Material used are compatible or better that those used by O.E.M.s.

Mostly used alloys: Inconel 738 LC - Inconel 792 - Inconel 939 M - GTD 111 - FSX 414 - EEQ 111 - N 155 - Alloy 247 - Udimet 500 - EEQ 222

Each and every Component is throughout inspected before the acceptance and the shipment to the next phase of production.

Inspection Protocol includes:

Chemical analysis - Stress rupture at high temperature - Tensile properties at ambient temperature - Tensile properties at high temperature - Hardness test - Macro etching - Micrography - Solution Heat treatment - Precipitation Heat treatment - Hipping -X-Ray - F.P.I. - Dimensional check - Visual Inspection

SECOND PHASE

Machining

Components are machined in accordance with Special Part’s drawings and specification.

Each and every Component is fully inspected before the acceptance and the shipment to the next phase of production.

Inspection Protocol includes:

X-Ray on cooling holes - F.P.I on machined surfaces - Dimensional Inspection - Visual Inspection

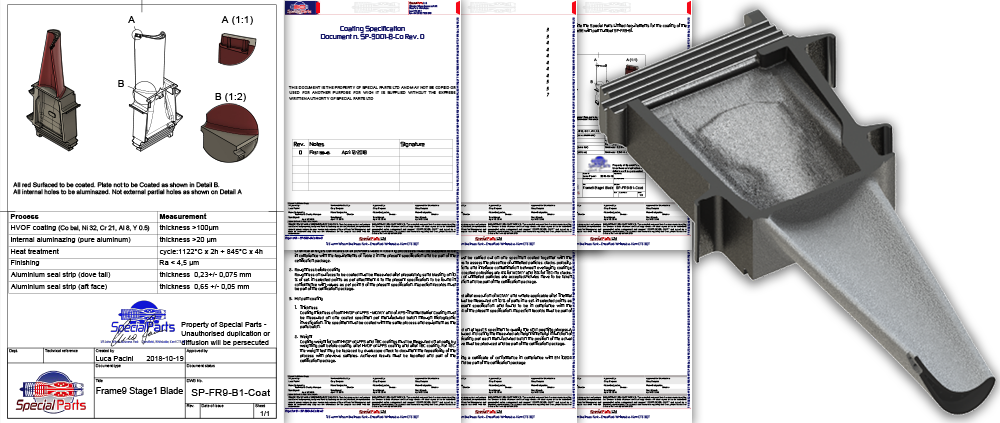

THIRD PHASE

Coating

Components are Coated, Balanced, and tested in accordance with Special Part’s drawings and specification.

Coatings Typically applied: MCrAlY - TBC - Internal Aluminising.

Each and every Component is fully inspected before the Final Acceptance and the shipment to the Customer

Inspection Protocol includes:

Powders Chemical analysis - Roughness before coating - Thickness test - Micrography - Roughness before TBC - Roughness after TBC - Visual inspection - Almen test - Precipitation Heat treatment - Moment weight - Air flow test

Coatings Typically applied: MCrAlY - TBC - Internal Aluminising.

Each and every Component is fully inspected before the Final Acceptance and the shipment to the Customer

Inspection Protocol includes:

Powders Chemical analysis - Roughness before coating - Thickness test - Micrography - Roughness before TBC - Roughness after TBC - Visual inspection - Almen test - Precipitation Heat treatment - Moment weight - Air flow test

FOURTH PHASE

Inspection and documents Release

All the parts produced are checked and inspected. All the test reports are analysed and approved.

Complete Manufacturing Test Reports related to Casting - Machining and Coating and traceability records are given to the customer if required.

© 2025 Special Parts Limited - All rights reserved