Blades and Vanes for Gas turbine Hot Gas Path are extremely difficult components to produce and cannot be manufactured in one single plant. Typically parts are produced in a lost wax investment casting foundry, refined in a superalloy machining shop and finished in a coating shop.

SP role is to distribute to each plant the necessary drawings and manufacturing specification, to manage the supply chain and to check the quality of each production process.

SP role is to distribute to each plant the necessary drawings and manufacturing specification, to manage the supply chain and to check the quality of each production process.

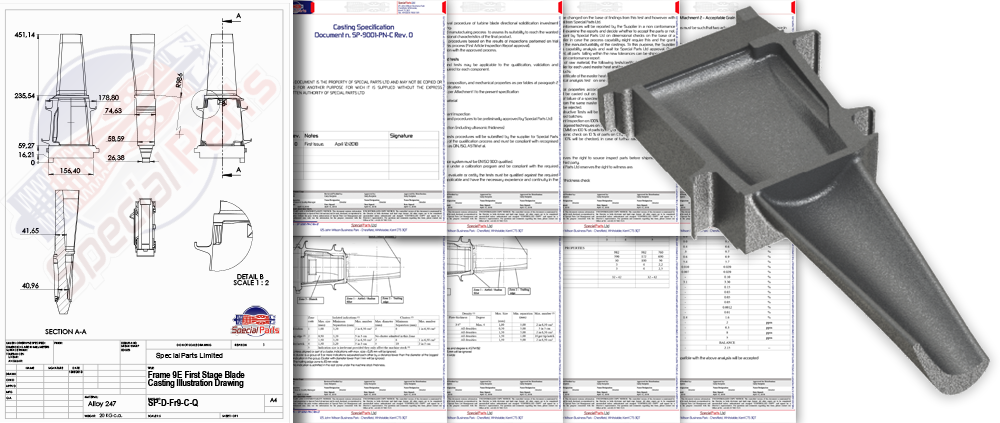

FIRST PHASE

Casting

Components are casted in according with Special Parts drawing and specification in some of the most renowned foundries in Western Europe. Material used are compatible or better that those used by O.E.M.s.

Mostly used alloys: Inconel 738 LC - Inconel 792 - Inconel 939 M - GTD 111 - FSX 414 - EEQ 111 - N 155 - Alloy 247 - Udimet 500 - EEQ 222

Each and every Component is throughout inspected before the acceptance and the shipment to the next phase of production.

Inspection Protocol includes:

Chemical analysis - Stress rupture at high temperature - Tensile properties at ambient temperature - Tensile properties at high temperature - Hardness test - Macro etching - Micrography - Solution Heat treatment - Precipitation Heat treatment - Hipping -X-Ray - F.P.I. - Dimensional check - Visual Inspection

Mostly used alloys: Inconel 738 LC - Inconel 792 - Inconel 939 M - GTD 111 - FSX 414 - EEQ 111 - N 155 - Alloy 247 - Udimet 500 - EEQ 222

Each and every Component is throughout inspected before the acceptance and the shipment to the next phase of production.

Inspection Protocol includes:

Chemical analysis - Stress rupture at high temperature - Tensile properties at ambient temperature - Tensile properties at high temperature - Hardness test - Macro etching - Micrography - Solution Heat treatment - Precipitation Heat treatment - Hipping -X-Ray - F.P.I. - Dimensional check - Visual Inspection

SECOND PHASE

Machining

Components are machined in accordance with Special Part’s drawings and specification.

Each and every Component is fully inspected before the acceptance and the shipment to the next phase of production.

Inspection Protocol includes:

X-Ray on cooling holes - F.P.I on machined surfaces - Dimensional Inspection - Visual Inspection

Each and every Component is fully inspected before the acceptance and the shipment to the next phase of production.

Inspection Protocol includes:

X-Ray on cooling holes - F.P.I on machined surfaces - Dimensional Inspection - Visual Inspection

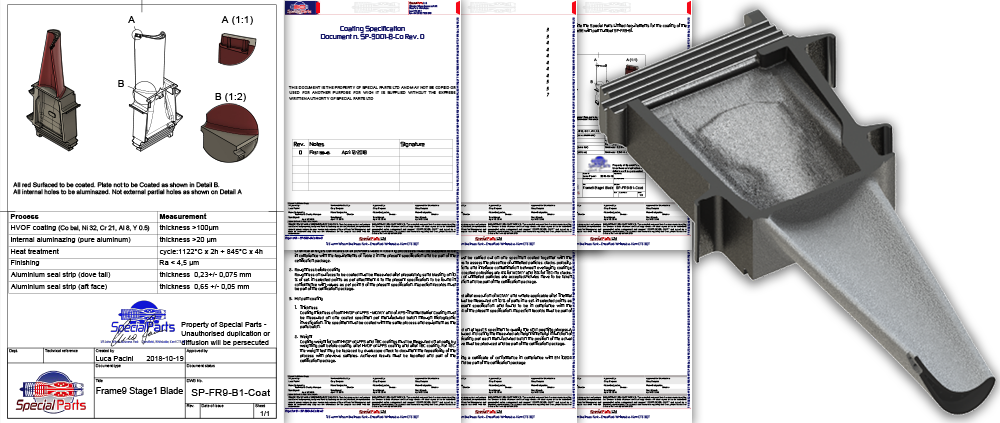

THIRD PHASE

Coating

Components are Coated, Balanced, and tested in accordance with Special Part’s drawings and specification.

Coatings Typically applied: MCrAlY - TBC - Internal Aluminising.

Each and every Component is fully inspected before the Final Acceptance and the shipment to the Customer

Inspection Protocol includes:

Powders Chemical analysis - Roughness before coating - Thickness test - Micrography - Roughness before TBC - Roughness after TBC - Visual inspection - Almen test - Precipitation Heat treatment - Moment weight - Air flow test

Coatings Typically applied: MCrAlY - TBC - Internal Aluminising.

Each and every Component is fully inspected before the Final Acceptance and the shipment to the Customer

Inspection Protocol includes:

Powders Chemical analysis - Roughness before coating - Thickness test - Micrography - Roughness before TBC - Roughness after TBC - Visual inspection - Almen test - Precipitation Heat treatment - Moment weight - Air flow test

FOURTH PHASE

Inspection and documents Release

All the parts produced are checked and inspected. All the test reports are analysed and approved.

Complete Manufacturing Test Reports related to Casting - Machining and Coating and traceability records are given to the customer if required.

Complete Manufacturing Test Reports related to Casting - Machining and Coating and traceability records are given to the customer if required.

Manufacturing and Procurement Made Easy

SP - Your Bridge to the Engineering and Manufacturing World

© 2022 Special Parts Limited - All rights reserved