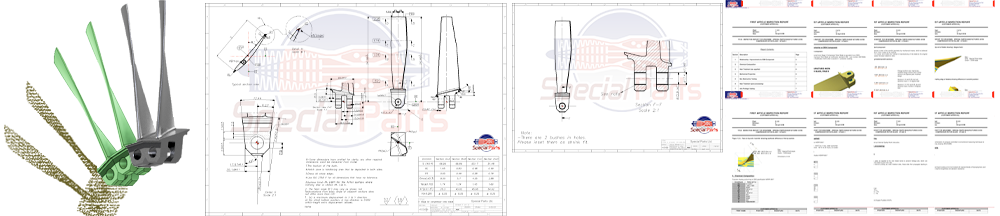

Compressor Blades and Vanes

High-Quality compressor blades and vanes for inland Gas Turbines

Special Parts has a large variety of ready to order compressor blades for GE, Siemens and Rolls-Royce produced gas turbines.

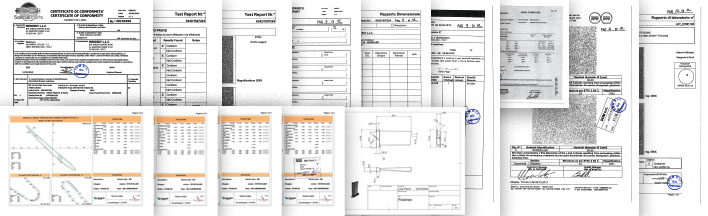

Quality Assurance

All parts are coated if required and accompanied by comprehensive test reports

✓

Frequency test

✓

F.P.I Testing

✓

X-ray Inspection

✓

Moment Weight

In order to produce high quality aftermarket turbine parts, mastering all the Reverse Engineering processes and the most advanced technologies is a condition but it is not sufficient enough.

Quality with short lead time to market

Special Parts has a long established manufacturing experience for a wide range of Turbine products and long term business relationship with first class manufacturing facilities.

Special Parts's strong coordination with its supply chain Partners during the performance of the Reverse Engineering and Product Development activities guarantees an incredibly efficient and consistent planning of the production process and a highly reduced time to market.

New Production from Samples - Process Phases

Special Parts's Engineers have long experience in develop new products from samples. From Turbine blades to combustion chambers to casings Special Parts handles all the phases of the Reverse Engineering and Development process.

Quality with short lead time to market

Special Parts has a long established manufacturing experience for a wide range of Turbine products and long term business relationship with first class manufacturing facilities.

Special Parts's strong coordination with its supply chain Partners during the performance of the Reverse Engineering and Product Development activities guarantees an incredibly efficient and consistent planning of the production process and a highly reduced time to market.

New Production from Samples - Process Phases

Special Parts's Engineers have long experience in develop new products from samples. From Turbine blades to combustion chambers to casings Special Parts handles all the phases of the Reverse Engineering and Development process.

FIRST PHASE

3D SCANNING - DRAWINGS AND MATERIAL SPECIFICATION DRAFTING

One or more samples are used to determine the Material and Shape of the component.

For each stage of the production, complete manufacturing documentation, drawings and Quality Acceptance Protocols are drafted.

SECOND PHASE

PLANNING OF MANUFACTURING PROCESS AND SELECTION OF THE SUPPLY CHAIN

The design of all the required tooling is drafted.

The planning and the validation of all the

production activities is agreed with all the

suppliers involved.

THIRD PHASE

TOOLING MANUFACTURING - TRIALS AND FAIR

Under SP Supervision, each company within the supply chain

produces several trial parts in order to perfect the manufacturing

processes and to guarantee continued repeatability of the

quality requirements during the production.

All relevant parameters and data are registered in the FAIR (First Article Inspection Report )

FOURTH PHASE

PRESENTATION OF THE FAIR AND CUSTOMER APPROVAL

The complete FAIR is consigned to the customer for its evaluation and approval. The production is ready to start

Technical characteristics and production processes of compressor rotor and stator blades and steam turbine blades largely vary with respect to the application they are made for.

Material span stainless steel to nickel alloys to titanium alloys while shape and dimensions may vary from few millimiters till 1.500 millimiters.

Typically parts are produced by several machining processes starting from forged raw blades or bars. Additional operations like welding of multiple airfoils, coating or brazing may be required.

SP role is to distribute to each plant the necessary drawings and manufacturing specification, to manage the supply chain and to check the quality of each production process.

Material span stainless steel to nickel alloys to titanium alloys while shape and dimensions may vary from few millimiters till 1.500 millimiters.

Typically parts are produced by several machining processes starting from forged raw blades or bars. Additional operations like welding of multiple airfoils, coating or brazing may be required.

SP role is to distribute to each plant the necessary drawings and manufacturing specification, to manage the supply chain and to check the quality of each production process.

MAIN PHASES OF THE PRODUCTION PROCESS

INSPECTION, QUALITY AND DOCUMENTATION

All the parts produced are checked and inspected. All the test reports are analysed and approved.

Complete Manufacturing Test Reports related to Forging, Machining, Welding and Coating and traceability records are given to the customer if required.

© 2025 Special Parts Limited - All rights reserved